Carol Motycka, PharmD, BCACP

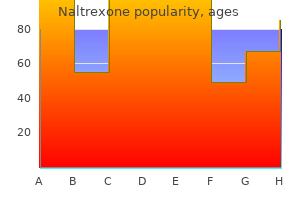

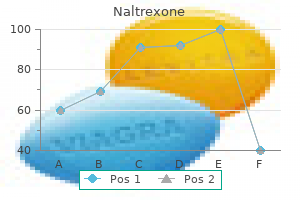

Naltrexone dosages: 50 mg

Naltrexone packs: 10 pills, 20 pills, 30 pills, 60 pills, 90 pills

Validation of closure washing medications safe while breastfeeding order naltrexone 50 mg amex, apart from the essential part of endotoxin reduction, is typically complemented with data on other closure properties, such as microbiological cleanliness of the parts after the depyrogenation process, reduction of particulate burden by washing, particulate cleanliness of washed and dried parts, siliconization level after drying, and absence of washing detergent. Parenteral Medications by terminal sterilization whereby the packaging components are already assembled. Of course, every sterilization process of packaging components shall be validated. It is worth mentioning that steam sterilization cannot serve as a depyrogenation process. As mentioned before, steam sterilization puts a considerable amount of moisture into elastomeric closures. Therefore, after steam sterilization, closures shall be dried again using appropriate procedures that take into account the sensitivity of the drug product to residual moisture that might be transferred from the closure. Closures for lyophilization applications, therefore, will often be dried to lower residual moisture than closures for liquid fills. In a number of cases, drying times of only 1 h are applied; in other cases, drying cycles of up to 16h are qualified. Other than the moisture uptake, steam sterilization of elastomeric closures, followed by drying, will not affect their functional properties. This still holds when the cycle is applied more than once on the closures, albeit this is not encouraged, and for multiple sterilizations, a check on closure functionality may be indicated depending on the exact use of the closure in question. Dry heat instead of moist heat sterilization of elastomeric closures is totally advised against. Sterilization by Irradiation Of increasing importance is the use of irradiation sterilization for elastomeric closures. Sterilization by beta irradiation of elastomeric closures is not excluded; however; gamma irradiation, because of its much higher penetration capability, is preferred.

In some instances medicine ethics purchase 50 mg naltrexone, it is possible that the energy absorbed by a nondrug molecule (photosensitizer) in the formulation is transferred to the drug molecule which eventually degrades. Examples of some common drugs that undergo photolytic degradation include methotrexate, furosemide, and tetracyclines. For many drug substances, the kinetics of photodegradation vary significantly with the ionization state of the molecule. Control of pH, ionic strength, trace metals, or even use of complexants25 are formulation approaches that can also address such instability. In addition to these major modes of degradation, many other routes are involved in drug degradation, such as decarboxylation, racemization/epimerization, and acylation. Understanding the causes of drug instability allows rational design of a formulation. Form Selection the solid form of the drug compound can have a significant effect on parenteral drug product processing. The solid form is typically described by the salt form used and the crystal polymorph of the chosen salt. Salt Form Many drugs are either weak acids or weak bases and consequently can form a range of salts by reacting with various bases and acids, respectively. Salt formation may be employed to alter the physicochemical, biopharmaceutical, and processing properties of a drug substance without modifying the pharmacologically relevant moiety. Thus, for a basic drug, pKa of the basic center will determine what salts are feasible. In the case of parenteral medications, increased solubility is often desired from chosen salts. In general, utilizing counterions with greater acidity, utilizing more hydrophilic counterions (hydroxy acids), and lowering the melting point of the resultant salt (decreased crystal lattice energy) can result in increased solubility. In the case of solution formulations, it is not essential that salt formation is only employed for obtaining a suitable solid form. Salts can be formed in situ in solutions by using the appropriate acidic or basic counterion to adjust the pH of the formulation. Preformulation Stability Studies Typically, the drug substance is studied in solid as well as solution state. These studies may be able to indicate not only potential need for protecting the drug product from light but also the need for conducting other stability studies under light protected conditions. The solutions are sampled at regular intervals and analyzed using a stability indicating method. The time course of degradation at a particular pH can typically be expressed as the firstorder rate constant kobs (k observed). A log kobs versus pH plot is referred to as the pH-rate profile and can be quite revealing of the mechanisms involved in drug degradation. The pH of maximum stability would be targeted as the pH for the formulation as long as it agreed with the required solubility and local tolerability at that pH. During preformulation studies, it may also be necessary to evaluate drug stability under potential processing conditions.

Diseases

Concentrations between 400 and 650 mg/L are recommended for effective microbial inactivation and more efficient gas removal from product at completion of the sterilant exposure medicine zanaflex discount naltrexone 50 mg. A third type, X-rays, has been shown to have microbicidal effects, but this method is not currently available for industrial sterilization. The microbial lethality of gamma rays and electrons is accomplished by ionization; electrons are direct ionizing radiation, whereas photons are indirect ionizing radiation. The energy transferred by these radiations during the sterilization process produces chemical and/or physical changes at the molecular level, resulting in chain scission, polymerization, cross-linking, sterilization, and disinfection. Physical Characteristics of Radiation By far, the most commonly used of the three methods is gamma radiation. Gamma rays are emitted from radioactive isotope source materials, the most common being cobalt 60 (60Co). Having no electric charge or mass, photons transfer energy to materials mainly through Compton scattering collisions with atomic electrons resulting in a uniform, exponentially decreasing depth dose distribution. The photon strikes free electrons in the material and passes part of their energy to the electron as kinetic energy. These displaced electrons continue on their way, deflected from their original path. The scattered gamma ray carries the balance of the energy as it moves off through the material, possibly to interact again with another electron. It is the cascade of electrons that result in the physical and chemical changes in the material as well as the destruction of microorganisms. Because the probability of Compton scattering is low, the primary beam of gamma rays will penetrate long distances in material before the scattering occurs. This means that the gamma rays deposit energy over a relatively large area so that penetration is high (up to 50 cm), but the dose rate is low (Table 30. In fact, as soon as charged particles penetrate solid materials, they are subject to the Coulomb force exerted by the atomic nuclei and are therefore in almost constant interaction with the material. These interactions result in many directional changes, ionizations, and radioactive processes that slow the electrons and ultimately limit their penetration to only 5 cm into material with a density of 1. E-beam energy is therefore deposited within materials over a short distance making the dose rate very high (22,000 kGy/h for a 50-kW beam) allowing sterilization to take place in less than 1 min. The parameter measuring the energy transferred from the radiation source to the product is called the absorbed dose. The penetration of gamma rays and electrons is inversely proportional to product density. The absorbed dose is the quantity of ionizing radiation energy imparted per unit mass of a specified material and is expressed as the Gray (Gy) where 1 Gy = 100 Rads or 1 kGy = 0.

Were the process to be operated at precisely the conditions where the D-value has been determined symptoms kidney stones naltrexone 50 mg generic, initial validation 697 and day-to-day process control would be greatly simplified. Unfortunately, it is extremely difficult to provide constant process conditions (fixed temperature for the entire sterilization cycle) in routine sterilization process on a commercial scale. There are many real-world factors that prevent constant conditions in production settings including chamber size, load size, item complexity, item wrapping materials, and item orientation. To accommodate these elements, a means for relating physical conditions at varying temperatures to microbial destruction is necessary. The D-value, which is essentially the rate at which microorganisms are killed, is predominantly a function of the temperature-the higher the process temperature, the more rapid the destruction of microorganisms. The General Method for sterilization process evaluation uses this temperature dependency to allow for the estimation the lethal effect on microbes at a range of temperatures near the D-value [6,7]. The General Method estimates the lethality over the process duration by calculating the kill rate for microorganisms as the temperature progresses through the sterilization cycle. When first developed, the concern was food safety and the potential survival of Clostridium botulinum in canned foods. Simple mathematics can be utilized to calculate estimated lethality at other temperatures using the lethality equation. For parts sterilization, it begins during the come-up and ends when evacuation of the chamber begins at the conclusion of the dwell period. Probability of a Non-sterile Unit the duration of sterilization process is chosen to deliver lethality sufficient to confidently destroy the microorganisms present. Sterilization processes by their very nature incorporate conditions that have a deleterious impact on the materials being sterilized. The extreme temperature and moisture conditions that are microbiologically lethal can readily alter the chemical and physical properties of many materials. In the sterilization of stainless steel, glass, or most other equipment items, the adverse material effect is minor or non-existent. This can be compared to jumping over a hurdle; clearing the hurdle by an excessive height has no measurable adverse effect. Where the items being sterilized are subject to damage by the sterilization Study No.

It is desired to make a 2 g/100 mL solution of sodium cephalothin isotonic using sodium chloride treatment 5th metacarpal fracture 50 mg naltrexone for sale. Solutions may also exert less (hypotonic) or more (hypertonic) osmotic pressure than plasma. Red blood cells (erythrocytes) when introduced into hypotonic solution will swell and often burst (hemolysis) because of diffusion of water into the cell. If the cells are placed into hypertonic solutions, they may lose water and shrink (crenation). Isotonicity of formulation is not always feasible as a result of the high concentrations of drug utilized, the low volumes required for some injections, the wide variety of dose regimens and methods of administration, and product stability considerations. Historically, there has been concern over the osmolarity or tonicity of intravenous infusion fluids because of the large amounts of solution administered to hospitalized patients, but in the last few years, there has also been interest in the osmolarity of other parental dosage forms. Sodium or potassium chloride and dextrose are commonly added to adjust hypotonic solutions. The sodium chloride equivalent of a substance can be determined from its ability to lower the freezing point of water. This distinction is necessary because of the variable diffusibility of different medicinal substances across the cell membrane, which does not always behave as a truly semipermeable membrane. Solutions that are theoretically isoosmotic with the cells may cause hemolysis because solutes diffuse through the cell membrane. If a solution is hypertonic, not much can be done with the formulation unless it can be diluted with water prior to administration. Administration of a hypertonic solution should be done slowly to permit dilution by the blood. In some cases, where injection of such solutions produces pain, as in an intramuscular injection, a local anesthetic may be added. The effect of isotonicity on reducing pain on injection is somewhat vague, although it may at least reduce tissue irritation. The sodium chloride equivalent method was used for determining the osmolarity of a number of infusion solutions and compared with measured values. Osmolality Percent of Measure Special Types of Parenterals Suspensions A parenteral suspension is a dispersed, multi-phased, heterogeneous system of insoluble solid particles intended principally for intramuscular and subcutaneous injection. Suspension formulation is desired when the drug is too insoluble or unstable to be formulated as a solution, as well as when there is a need to retard or control the release of drug from a suspension. The desirable parenteral suspension is sterile, stable, resuspendable, syringeable, injectable, and isotonic/nonirritating. Because a delicate balance of variables is required to formulate a suitable product, a suspension is one of the most difficult parenteral forms to prepare. To achieve these goals, it is necessary to control the crystallization, particle size reduction (micronization), and sterilization of the drug substance, as well as the processes involved in wetting of the drug with surfactants, aseptic dispersion and milling, and final filling into containers.

Tear Fluid Osmolality the tear fluid osmolality normally ranges from about 300 to 320 mOsm/kg [3 medicine park lodging naltrexone 50 mg order online,12], and most of the osmolality in the tear fluid can be attributed to the salt content of the lacrimal fluid, which is primarily sodium chloride, sodium bicarbonate, potassium chloride, calcium chloride, and magnesium chloride [3]. Normally, there is about five times more sodium than potassium in the tear Development of Ophthalmic Formulations 5. The endothelium-composed of a single layer of flattened cells that are connected via tight junctions. It controls the hydration of the cornea by limiting access of water from the aqueous humor and by active transport mechanisms. The cornea provides a limited surface area of about 1 cm2 for drug diffusion and is a significant barrier to both hydrophilic and lipophilic compounds. Lipophilic molecules will diffuse more easily through the epithelium and the endothelium, but hydrophilic molecules will diffuse more easily through the highly aqueous stroma. The aqueous humor is composed mainly of water; high concentrations of ascorbic acid, glucose, and amino acids; and limited levels of proteins. Aqueous humor flows from the ciliary body in the posterior chamber (behind the iris) into the anterior chamber (between the iris and the cornea). Conjunctiva the conjunctiva is a thin mucus-secreting membrane that lines the posterior layer of the eyelids (palpebral conjunctiva), the anterior sclera (bulbar conjunctiva), and the superior and inferior conjunctival fornices (joining areas between the palpebral and bulbar conjunctiva). The conjunctiva is composed of two layers: an outer epithelium layer (which is continuous with the corneal epithelium) and an underlying stroma layer. The stroma layer of the conjunctiva contains the nerves, lymphatics, and blood vessels, and it attaches loosely to the sclera. The conjunctiva contributes to the tear film formation by secreting electrolytes, fluid, and mucin [20]. Vitreous Humor Vitreous humor is a gel-like material that occupies the space between the lens and the retina. It supports the posterior surface of the lens and helps keep the neural part of the retina in place. The close proximity of the vitreous to the retina and choroid makes this cavity a direct place for drug delivery to the posterior tissues. Retinal vessels supply the inner two-thirds, while the outer retina is avascular and receives oxygen and nutrients from the choriocapillaris. The choriocapillaris is fenestrated to enhance transport of nutrients to the underlying retina. Retinal capillaries are composed of a single layer of endothelial cells surrounded by a basement membrane and pericytes.

Dog Standard (Tansy Ragwort). Naltrexone.

Source: http://www.rxlist.com/script/main/art.asp?articlekey=96280

These preservatives are added in low concentrations; however treatment nerve damage naltrexone 50 mg buy fast delivery, they have a tendency of being ad/absorbed by rubber thus losing their effect in the drug solution. Depending on the combination of type and concentration of preservative and type of rubber compound, this absorption can be more or less pronounced. Development of new rubber compounds and development of drug formulations must take this phenomenon into account. Water may cause a local discoloration where it is in contact with the closure; for example, a dark gray stopper may discolor to a lighter gray. This discoloration is not of any functional concern and can be reversed by drying the stopper. In contrast with water, other drug diluents may display a higher amount of absorption into the rubber closures. They cause a clearly measurable increase in the weight and, in forthcoming cases, in the dimensions of rubber closures. Mineral oils, on the other hand, will cause a much higher swelling in halobutyl stoppers and therefore are incompatible with them. In such cases, either the use of special rubber formulations (nitrile rubber) or of coated closures is indicated. Apart from the purely physical effect of swelling, the diluent that penetrates the closure and is absorbed there may also dissolve rubber chemicals and act as carrier for leachables into the drug solution. Chemical Properties Extractables according to Pharmacopeial Methods Rubber compounds are composed of different materials that have been vulcanized through a curing step at elevated temperature. In contact with a drug solution, some of these materials, their impurities, their reaction products, or their thermal breakdown products may be extracted from the rubber closure. A common way to make an assessment of extractables from pharmaceutical rubber is to prepare an extract of the rubber under well-defined model conditions and then, by using primarily wet chemistry methods, to measure for extractables. The Japanese Pharmacopoeia is an exception in that the extraction time is not 30 but 60 min. The types of physicochemical tests in the various pharmacopoeia and the limit values over time have remained rather static. This is the result of new regulations having come into place that limit the presence of elemental impurities in drug products. Since primary packaging materials, including elastomeric closures, can contribute to the level of elemental impurities in drugs, they are also indirectly affected by these regulations. Methods are upcoming to measure the presence of elemental impurities in extracts of elastomeric closures with modern instrumental analytical techniques. Examples of deterministic methods are highvoltage leak detection and laser-based gas headspace analysis.

These variants possess properties comparable to the desired product and are not considered impurities [6] medicine journals impact factor discount naltrexone 50 mg free shipping. Aluminum catalysis of epinephrine degradation in lidocaine hcl with epinephrine solutions. The formation of aluminumepinephrine complex and its effect on the addition of bisulfite to epinephrine. Thresholds and best practices for leachables and extractables in parenteral and ophthalmic drug products working group, work plan. Impact of elastomer extractables in pharmaceutical stoppers and seals; material supplier perspective. Bisharan R, Dicthe D, Feld S-A, Grusgaard J, Patrick D, Seevers B, Smith E, Ulrich D, Weirich W, Womastek K. Guidance for temperature-controlled medicinal products: maintaining the quality of temperature-sensitive medicinal products through the transportation environment. Proceedings of the 2nd International Conference on Particle Detection, Metrology and Control, Parenteral Drug Association/Institute of Environmental Sciences. Neutraplex - tubular glass vials with improved hydrolytic resistance for pharmaceuticals. Tygon is a registered trademark of Saint-Gobain Performance Plastics Corporation. Discussion of the physiochemical factors that regulate the leaching of organic substances from plastic contact materials into aqueous pharmaceutical solutions. Modeling of the solution interaction properties of plastic materials used in pharmaceutical product container systems. Essential elements of extractables and leachables: from material selection to final report. Polymeric components and systems used to manufacture pharmaceutical and biopharmaceutical drug products. Characterization of polymeric components and systems used to manufacture pharmaceutical and biopharmaceutical drug products.

Physical integrity of the container as a means to maintain product sterility is another equally important requirement of containers for parenterals treatment interventions best naltrexone 50 mg. In this respect, the mechanical and thermal characteristics of glasses must be considered. Describing glass as a "brittle" material is, perhaps, consistent with the general perception that glass is fragile. However, as material science terms, brittle and elastic have more precise meanings, both of which apply to glasses. In this context, brittle refers not to the strength of the material but to the failure mode when localized stresses exceed local bond strength. Most metals, when overloaded, will deform in a permanent way, technically, "plastic deformation," before breaking. Brittle materials, such as glasses, are unable to undergo plastic deformation and, therefore, break abruptly (87, 88). Intrinsically, glasses are very strong in response to compressive loads, but can break when placed under sufficient tension. The practical strength of glass is limited by flaws (also referred to as surface damage, or discontinuities), which are cuts or gaps in the atomic bonds at the glass surface. These flaws concentrate the applied tensile load at their tip and will grow (form a crack or break) if the concentrated tension exceeds the strength of individual atomic bonds. Thus, the flaw or discontinuity effectively reduces the practical strength of the material as elucidated by Griffith (89). Similarly, as a material science term, elastic refers to the response of a material to the application and removal of a mechanical load that does not exceed the strength of the material. Elastic materials deform when loaded and then return to the original shape when the load is removed. Although it was not the objective of the studies, the work demonstrates the elastic deformation of the glass in response to the changing physical dimensions of the contents. Because of the combination of stiffness, brittle behavior, and reduction in strength at surface flaws, one does not usually observe directly the elastic deformation that occurs in glass containers before catastrophic brittle failure occurs. Indirectly, when failure occurs, the energy stored by elastic deformation may be observed in the form of rapid fracture propagation and dispersion of the glass fragments. Stress in glass containers can result from forces exerted on the container, either externally or internally. Stress can also be the indirect result of nonhomogeneous composition (called cord) or other imperfections from the melting process or from thermal effects.

Stability of IgG1 monoclonal antibodies in intravenous infusion bags under clinical in-use conditions treatment kidney stones buy naltrexone 50 mg on-line. Disposable technology for controlled freeze-thaw of biopharmaceuticals at manufacturing scale. Guidance for Industry: Container Closure Systems for Packaging Human Drugs and Biologics-Chemistry, Manufacturing, and Controls Documentation. Robust and convenient single-use processing: the superior strength and flexibility of flexsafe bags. Disposable bioreactors: the current state-of-the-art and recommended applications in biotechnology. Properties of materials used in used in single-use flexible containers: Requirements and analysis. Quantification of protein adsorption onto the surface of single-use flexible containers. Strategy for selecting disposable bags for cell culture media applications based on a root-cause investigation. Analysis and evaluation of single-use bag extractables for validation in biopharmaceutical applications. Japanese Pharmacopoeia Sixteenth Edition, Plastic containers for pharmaceutical products. Taking one step back, many parenteral product formulations, and even active ingredients, must be aseptically stored prior to filling into the final product-package system. To make matters even more challenging, finished product, bulk formulation, and active substance package systems vary extensively in design and materials of construction. Even selecting one appropriate method for any given product-package system can be daunting. Microbial immersion challenge and tracer liquid tests have historically been considered appropriate package integrity tests and continue to be used. With the advent of new technologies, various sensitive and dataproducing test methods have been developed to bring package integrity testing into the 21st century. The demands placed on parenteral product packaging often exceed the requirements of other dosage form containers. Clearly, all pharmaceutical product-package systems must prevent content leakage or spillage. But for some parenteral product-packages, product loss includes vacuum loss or escape of inert gases or solvent vapors. All pharmaceutical packages must prevent contamination from environmental dirt or debris and must also preclude microorganism contamination. For some parenteral products, contamination may include unwanted chemicals, even moisture, originating from the outside environment or leaching from the package components themselves. A typical vial package is comprised of a glass or plastic vial or bottle stoppered with a viscoelastic closure compressed against the vial land seal and held in place via a crimped aluminum cap.

Copper, 39 years: Regardless of the criterion and data set utilized, the most important consideration is the frequency of execution. Larger size protein aggregates, with diameters closer to the incident beam wavelength, cause interference (reduction in intensity) of the scattered light emanating from different parts of the molecules. Stability studies of Trp amino acid alone in aqueous solution (64) and Trp residues in small peptides and lysozymes (65) and in bovine -crystallin (66) clearly identified the main degradants as 5-hydroxy-Trp, oxy-indole alanine, kynurenine, and N-formylkynurenine. Through this opening, sublimation of the ice takes place under the influence of underpressure in the lyophilization chamber and heat that is transmitted by the heat-exchanging liquid that circulates in the hollow shelves of the freeze dryer.

Hogar, 61 years: H represents the differential heat of solution and is calculated from the slope H of the line, -. More specialized syringes ranging in size from 50 to 125 mL have been developed for use with X-ray contrast media that are dosed by X-ray power injectors for procedures such as computed tomography imaging and cardiovascular angiography [36]. As such, these external activities can also contribute to the contaminants present [4]. Particulate contamination on elastomeric closures may still have the same material identity as the closure itself, may be part of the ingredients of that closure formulation (endogeneous particles), or may be contamination from the manufacturing environment that either has not been removed by washing or that is the effect of or a recontamination after washing (exogeneous particles).

References